|

Product |

|||||||

|

|

|||||||

|

Dyeing Lab. Equipment |

|||||||

|

|

|

|

|

||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

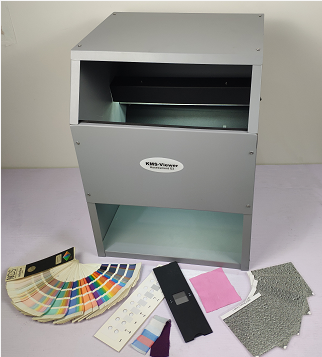

Application: |

|||||||

|

- |

Tools for viewing color samples under difference light to inspect metamerism. |

||||||

|

Features: |

|||||||

|

- |

Compliance to ASTM D1729, ISO 3664 as well Munsel grey N7-8. |

||||||

|

- |

Provided with standard lamps from VeriVide, X-rite, GTI , Philips, GE -Walmart.Munsell |

||||||

|

|

|

||||||

|

Download

.pdf file |

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Exhaustion dyeing process |

||||||

|

Features: |

|||||||

|

- |

Graphic display, touch screnn controller

with 100 programs storage. |

||||||

|

- |

Suitable for most types of fibres, high

reproducibility at normal and high temperatures. |

||||||

|

- |

No need to open dye-pots to add chemicals during dyeing

(patented). |

||||||

|

- |

Free from Ethylene Glycol pollution, energy saving. |

||||||

|

- |

Safety design. |

||||||

|

Option: |

|||||||

|

- |

Program loading software included PC

software and interface cable. |

||||||

|

|

|

||||||

|

Download .pdf file

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Drum dyeing type pot , suitable for small quanitity materials dyeing, such as garment accessories. |

||||||

|

Features: |

|||||||

|

- |

Difference textile fibres. |

||||||

|

- |

Temp. raised up to 140C for Polyester dyeing .fibres |

||||||

|

- |

Safety device on each dyeing pot. |

||||||

|

|

|

||||||

|

Download .pdf file

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Tools in the dyeing lab. to auto open difference dyes con'c solution , avoiding human error. |

||||||

|

Features: |

|||||||

|

- |

5 diff. preparation method, included hot water and cold water. |

||||||

|

|

|

||||||

|

Download .pdf file

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Supporting facilities to

ODM auto-dose & dyeing machine of imitation of production dyeing process

of continue dosing chemical, such as soda ash . Or other similar laboratory

dyeing machine application.

|

||||||

|

Features: |

|||||||

|

- |

Direct auto caculate dosing amount and dosing .

Fast, accuracy, easy operation, minus human error.

|

||||||

|

- |

One unit CSM -D can supply to muti units ODM or

any similar function dyeing machine.

|

||||||

|

- |

Simultaneously dosing 6 x beaker either same volumn

or different volumn according to ie, soda ash con'c and recipe amount.

Clean and less human work .

|

||||||

|

- |

6 x 3kg/0.1 g electronic balance for DP application with

weight is display on control panel.

|

||||||

|

- |

Table top design.

|

||||||

|

Option: |

|||||||

|

|

|

||||||

|

Download .pdf file

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Stirring of dyestuff, auxilliaries solutions |

||||||

|

- |

Stirring of lab samples in auxilliaries solution ( with sample holders)

|

||||||

|

Features: |

|||||||

|

- |

Stirring: can be set to stir fast, slow or pause periodically, |

||||||

|

thus provides effective stirring of aqueous, dispersion of dyestuff |

|||||||

|

such as Disperse Dyes, preventing deposits of dye particles onto |

|||||||

|

the side or bottom of containers. |

|||||||

|

- |

Keep Warm stirring at about 40 ~ 50 will enhance the dispersion of some auxilliaries and disperse |

||||||

|

dyes that maximize their dispersion under warm conditions. Heat Up to raise to and maintain at |

|||||||

|

higher temperatures, e.g. >80 ; or use of hot water for keeping temperatures up to

over 90 . |

|||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Atmospheric constant temp. or

gradient curve dyeing |

||||||

|

- |

Soaping or fixing agent process |

||||||

|

- |

Chemical treatment |

||||||

|

Model: |

|||||||

|

- |

OSM-12 |

||||||

|

- |

OSM-24 |

||||||

|

Features: |

|||||||

|

- |

12/24 250ml glass conical flash

beaker with silicone lid. |

||||||

|

- |

Screw litre

type lid an reguest. |

||||||

|

- |

1 oscillation water bath with a rail

design, quite operation. |

||||||

|

- |

1 UPC controller to control temp. and time setting. |

||||||

|

- |

Temp. control

up to approx. 95 . |

||||||

|

- |

Less water vapour,

clean envirnoment |

||||||

|

- |

Variable speed to and fro up to approx 100/min. |

||||||

|

|

|

||||||

|

Download .pdf file |

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Labortary dyeing machine with

provide simulating auxiliary chemical auto-dosing in plant production , continue and

times for dosing chemical, such as soda ash.

|

||||||

|

Model: |

|||||||

|

- |

ODM-8

|

||||||

|

- |

ODM-12

|

||||||

|

Features: |

|||||||

|

- |

The chemical dosing frame and dyeing machine can be

combined to use, and also seperated use as individual machine.

|

||||||

|

- |

One unit CSM -D can supply to muti units ODM or

any similar function dyeing machine.

|

||||||

|

- |

The dosing frame installed with 8 or 12 speed adjustable

dosing valves to dispense, ie soda ash solution continue

to each dyeing bath in setting time period.

|

||||||

|

- |

he chemical dosing frame installed with individual upc

controller. So it can be tailor make applied to other lab. atmosphere

dyeing machine, not only ODM machine.

|

||||||

|

Option: |

|||||||

|

|

|

||||||

|

Download .pdf file

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

For water,chemical padding or dyes padding |

||||||

|

Features: |

|||||||

|

- |

Simple and easy operation. |

||||||

|

- |

Vertical type padder. |

||||||

|

|

|

||||||

|

|

Download .pdf file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

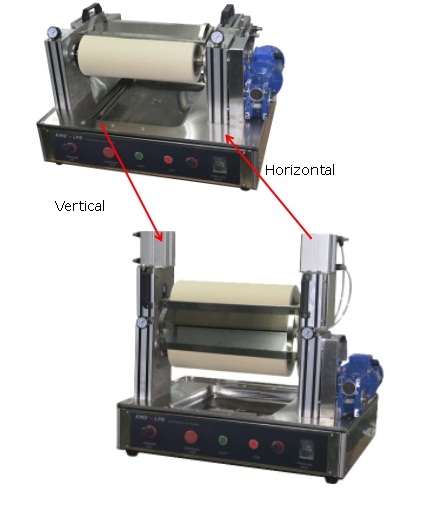

Application: |

|||||||

|

- |

Designed specifically for dye padding |

|

|||||

|

- |

Dual position Vertical

and Horizontal padder. |

||||||

|

|

|||||||

|

- |

With safety device and

emergency hand and foot paddle stop. |

||||||

|

- |

Dia. 150mm padder, good penetration and high reproducibilty.

|

||||||

|

- |

Left and right

pressure gauges |

||||||

|

- |

Options : |

||||||

|

|

1. Inverter

speed control |

||||||

|

|

2. Guiding

frame with fabric J plate for vertical position |

||||||

|

|

3. Special rubber

resistance to silicate |

||||||

|

|

Download

.pdf file |

||||||

|

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Padding and winding the rolls to check con t range dyeing tailing effect as well CPB (cold pad batch) |

||||||

|

Features: |

|||||||

|

- |

According to difference purpose, provided with difference support facilities, such as batching device, cooling device , conditioning cabinet. |

||||||

|

- |

Special rubber for resistance CPB process alkai. |

||||||

|

|

|

||||||

|

Download .pdf file

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Color fixation for pad & print samples. |

||||||

|

- |

Drying , Curing , and Steaming process. |

||||||

|

Features: |

|||||||

|

- |

External heating elements for flexible process. |

||||||

|

- |

Rotating frame to provide

even fixation result. |

||||||

|

- |

Energy saving for cycling heat with auto valves and controller control. |

||||||

|

|

|||||||

|

|

Download

.pdf file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Mainly applied for multi layer steaming pad & print samples. |

||||||

|

Features: |

|||||||

|

- |

External steam generator .

|

||||||

|

- |

Recycle steam to save engergy fibresas well improve envirnoment. |

||||||

|

- |

Safety device for steam pressure. |

||||||

|

|

|

||||||

|

Download .pdf file

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Twin individual chamber for 4 yarn cones drying after dyeing. |

||||||

|

Features: |

|||||||

|

- |

Sutiable for difference textile materials. |

||||||

|

- |

Auto-dry alarm to avoid overdry. |

||||||

|

- |

Inside-out as well outside-in hot air drying. |

||||||

|

|

|

||||||

|

Download .pdf file

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

For yarn cones hydroextraction as well fabric. |

||||||

|

Features: |

|||||||

|

- |

high speed up to 1250 rpm |

||||||

|

- |

wet weight up to 5.8kg |

||||||

|

|

|

||||||

|

Download .pdf file

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Magnetic printing for color-way sample |

||||||

|

Features: |

|||||||

|

- |

UPC controller auto operation |

||||||

|

- |

Store program for recall |

||||||

|

- |

Provided diff. Size of magnetic rod |

||||||

|

- |

Stroke speed control 0.6~6m/min |

||||||

|

|

|

||||||

|

|

Download .pdf file |

||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Used in textile finishing or drying. |

||||||

|

Model 1: DOC-9070 |

|||||||

|

- |

Room temp.+10 to 250 . |

||||||

|

- |

Chamber capacity 80 Litre. |

||||||

|

- |

Capable to hold 3 racks total . |

||||||

|

|

|

||||||

|

Model 2: DOC-9420A |

|||||||

|

- |

Room temp.+10 to 250 . |

||||||

|

- |

Chamber capacity 420 Litre. |

||||||

|

- |

Capable to hold 8~10 racks total . |

||||||

|

|

|

||||||

|

|

Download .pdf file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|

||||||

|

Application: |

|||||||

|

- |

Continuous sample drying / heat setting |

||||||

|

Features: |

|||||||

|

- |

Pin type. |

||||||

|

- |

Hot flue chamber 1.6m capacity. |

||||||

|

- |

PLC controller with drying, heat setting, and dwell time control. |

||||||

|

- |

Drying or heat setting temp. up to 200 . |

||||||

|

Option model: |

|||||||

|

- |

Continous with dwell time control by fabric temperature |

||||||

|

|

|

||||||

|

Download .pdf file |

|||||||

|

|

|

||||||

|

|

|||||||

|

|||||||

|

|

|

||||||

|

Application: |

|||||||

|

- |

Table type resin drying and curing |

||||||

|

Features: |

|||||||

|

- |

Automatic sample in, easy operation. |

||||||

|

- |

With temp. and time setting. |

||||||

|

- |

Temp. from room to 200 . |

||||||

|

|

|

||||||

|

|

Download .pdf file |

||||||

|

|

|

||||||

|

|

|

||||||

|

|

|||||||

|

|||||||

|

|

|

||||||

|

Models: |

|||||||

|

- |

CB-100CL |

||||||

|

- |

CB-250HC |

||||||

|

|

|||||||

|

Features: |

|||||||

|

- |

Cabinet type for sample conditioning. |

||||||

|

- |

Micro control temp. and % humidity. |

||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

|

|

||||||

|

Download .pdf file

|

|||||||

|

|

|

||||||

|

|

|||||||

|

|||||||

|

|

|

||||||

|

Application: |

|||||||

|

- |

Open air drying for delicate material |

||||||

|

Features: |

|||||||

|

- |

Avoid over drying. |

||||||

|

- |

With 2 blowing temp. |

||||||

|

|

|

||||||

|

|

Download .pdf file |

||||||

|

|

|||||||

|

|||||||

|

|

|

||||||

|

Download .pdf file

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

Application: |

|||||||

|

- |

Stenter frame machine, compacting machine, festoon steamer, inspection machine. |

||||||

|

Model: |

|||||||

|

- |

ES-S single water sprayer |

||||||

|

- |

ES-T

double-side water sprayer |

||||||

|

Features: |

|||||||

|

- |

Trend curve on-line

display of of moisture added. |

||||||

|

- |

Auto-syncing of spray

water amount with machince speed and fabric weight.

|

||||||

|

- |

Improved fabric

quality. |

||||||

|

- |

Optimised residual moisture on fabric. |

||||||

|

- |

Reduction of energy

cost. |

||||||

|

- |

Improve shrinkage. |

||||||

|

|

|

||||||

|

Download

.pdf file |

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

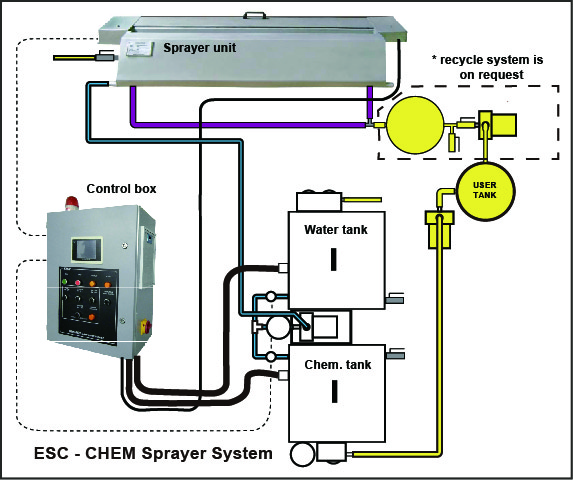

Application: |

|||||||

|

- |

Stenter frame machine, compacting machine, festoon steamer, |

||||||

|

Model: |

|||||||

|

- |

ESC-T double-side chem sprayer |

||||||

|

Features: |

|||||||

|

- |

Trend curve on-line display of of

moisture added. |

||||||

|

- |

Auto-syncing of spray water or chem

amount with machince speed and fabric weight. |

||||||

|

- |

Improved fabric quality. |

||||||

|

- |

Optimised residual moisture or chem

on fabric. |

||||||

|

- |

Reduction of energy cost. |

||||||

|

|

|

||||||

|

|

|||||||

|

Download .pdf file |

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

It is applied to continuous pad steam dyeing process, imitation of production condition. |

||||||

|

Features: |

|||||||

|

- |

Energy saving and stable steaming improving reproducibility. |

||||||

|

- |

Chamber capacity 6m. length. |

||||||

|

- |

Indirect steam pipe of ceiling to avoid condense water drops. |

||||||

|

- |

Entry / Exit frame and water seal, chamber run in roller up & down. |

||||||

|

- |

Emergency stop and tension sensor safety device. |

||||||

|

|

|

||||||

|

|

|||||||

|

Download.pdf file |

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

It is applied to continuous pad dry/thermosol dyeing process, imitation of production condition. |

||||||

|

Features: |

|||||||

|

- |

Recycle the exhaust hot air to HG for energy saving as well envirnoment. |

||||||

|

- |

Chamber capacity 6m. length. |

||||||

|

- |

Hot air flow on top & bottom, for even heating. |

||||||

|

- |

Padder with entry frame - roller up & down. |

||||||

|

- |

Emergency stop and tension sensor safety device for mc. stop and stop heating to prevent fabric melt or burnt. |

||||||

|

|

|

||||||

|

|

|||||||

|

Download.pdf file |

|||||||

|

|

|

||||||

|

|

|||||||

|

Testing Lab. Equipment |

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Colorfastess to light, perspiration-light fastness |

||||||

|

Features: |

|||||||

|

- |

Tabletop unit of simple operation. |

||||||

|

- |

Measure

control and display of BPT/BST, % RH, IRR and CHT (.display) |

||||||

|

- |

Record

the usage hours of Xenon lamp and warning of replacement. |

||||||

|

- |

Provided

ex-factory certificate and also verification report either used R4 SDC blue

wool or SDC VF 2950 CF. |

||||||

|

|

|||||||

|

Standards AATCC16-2014 Options 3 AATCC125, ISO 105-B02: 2014 Methods 3 and 4,JIS L0888 Methods, GB/T14576,GB/T8427(B02) |

|||||||

|

Option: |

PV1303

car accessories, GB/T 18753 printing ink |

||||||

|

|

Download .pdf

file |

||||||

|

|

|

||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

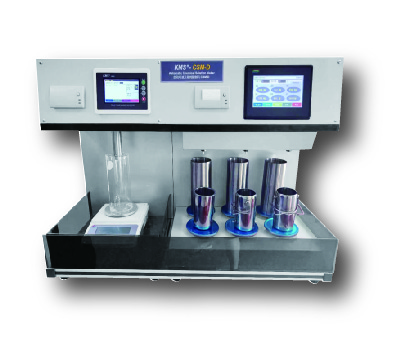

Application: |

|||||||

|

- |

Suitable for textile test centre , dyestuff & auxiliary chemical supplier or industrial with bulk washing fastness test daily activity. |

||||||

|

Features: |

|||||||

|

- |

One unit CSM can support several units of washing test machine. |

||||||

|

- |

Simultaneously dosing 6 wash pots with specified recipe within 1 to 2 minutes. Clean and reduce manual workload. |

||||||

|

- |

2 x Color display controller for CP & DP with narrow paper roll printer. |

||||||

|

- |

6 x 3 kg/0.1 g electronic balance for DP application, weight is displayed on control panel. |

||||||

|

|

|||||||

|

Standards Washing fastness test and etc |

|||||||

|

|

Download.pdf

file |

||||||

|

|

|

||||||

|

|

|||||||

|

|||||||

|

|

|

||||||

|

Application: |

|||||||

|

- |

Colorfastness to washing and dry-cleaning |

||||||

|

Features: |

|||||||

|

- |

UPC controller for time,

temp. gradient setting. |

||||||

|

- |

Available in 16 x 500ml or 1200ml wash

pots. |

||||||

|

- |

Options : Twin type wash pot

carrier. |

||||||

|

|

|||||||

|

Standards AATCC61, 86, 132, ISO 105-C06, C08, C10, E03 |

|||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|

||||||

|

|

|

||||||

|

|

|||||||

|

|||||||

|

|

|

||||||

|

Application: |

|||||||

|

- |

Colorfastness

to washing |

||||||

|

Features: |

|||||||

|

- |

UPC controller for time,

temp. gradient setting. |

||||||

|

- |

Available in 4 x 500ml or 1200ml wash pots. |

||||||

|

- |

It

selected an common used test std. stored for test. |

||||||

|

- |

one

touch operation |

||||||

|

|

|||||||

|

Standards AATCC61,

86, 132, ISO 105-C06, C08, C10, E03 |

|||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|

||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

To determine colorfastness to water and perspiration |

||||||

|

Features: |

|||||||

|

- |

All stainless-steel

perspiration kit. |

||||||

|

- |

UPC controller to

obtain accurate temp, inside incubator. |

||||||

|

|

|||||||

|

Standards AATCC 15, 106, 107, ISO 105-E04, E01, E02, yellowing Testing Kit |

|||||||

|

|

|

||||||

|

|

Download

.pdf file |

||||||

|

|

|

||||||

|

|

|||||||

|

|||||||

|

|

Download

.pdf file |

||||||

|

|

|

||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

To determine textile rubbing colorfastness. |

||||||

|

Features: |

|||||||

|

- |

Automatic rubbing |

||||||

|

- |

upc controller |

||||||

|

- |

magnetic fix and hold ,bring easy operation. |

||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

To determine textile Sublimation and hot press colorfastness |

||||||

|

Features: |

|||||||

|

- |

UPC controller. |

||||||

|

- |

Control heating and time |

||||||

|

- |

Time reached will alarm |

||||||

|

- |

Top plate with cooling fan, fast cool

down. |

||||||

|

|

|||||||

|

Standards ISO 105 , AATCC133,117 , GB5718,G152 |

|||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Textile,

Computer paint shop,Printing factories,Plastic

and Paper industries |

||||||

|

Features: |

|||||||

|

- |

Professional Complying with international standard. |

||||||

|

- |

Economic: Pay less and space save. |

||||||

|

- |

Practical: Pilling grading, grey

scale assessment and simple color matching in one go. With magnetic sample

sticker |

||||||

|

|

|

||||||

|

Download

.pdf file |

|||||||

|

|

|||||||

|

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Tensile strength test for yarn or fabric.

|

||||||

|

- |

Ball bursting test.(compress force)

|

||||||

|

|

|

||||||

|

Features: |

|||||||

|

- |

Auto return

after break, record

and display peak force and elongation%. |

||||||

|

- |

Choose

different force unit (gf, kgf,cN,

N or lbf

|

||||||

|

- |

Test

data can be printed out by build-in narrow printer. |

||||||

|

- |

Tensile

force and Compression force (eg. ball bursting)

allowed. |

||||||

|

Standards |

|||||||

|

- |

For yarn: ASTM D2256, ISO 2062

|

||||||

|

- |

ASTM

D5034, D5035, ISO13934-1/2 , ASTM D3787(compress force) |

||||||

|

|

|

||||||

|

|

Download .pdf

file

|

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Tensile strength test for yarn, fabric and elastic materials, on break force, cycle test, stretch recovery, seam slippage and elongation test. |

||||||

|

- |

PC computer type |

||||||

|

Features: |

|||||||

|

- |

Laptop with build-in

software and interface cable. |

||||||

|

- |

Default

international and enterprise textile testing standards installed in software

with simple recall process. |

||||||

|

- |

Provide variety of

grips, load cells for different test standards , |

||||||

|

- |

Choose different

force unit (gf, kgf, cN, N or lbf), data storage,

data recell and printing function provided. |

||||||

|

Standards |

|||||||

|

- |

ASTM

D5034, D5035, D2256, D4964, D434,D6614. D3822,

D4632, D885. D3107, D2261 |

||||||

|

- |

ISO 2062,

13934-2. 6939. 13936-1,2. 13937-2, 1421,2. ISO13539-1/2, 13934-1, 13935-2, |

||||||

|

- |

M&S.

P11, P12, P14, P15. |

||||||

|

- |

set force, set

distance, JIS L1096,Method1. 2, |

||||||

|

- |

BS 14704-1, 4952, 3320, DIN 53868 |

||||||

|

- |

LTD03, 11, 19, VSS03 |

||||||

|

- |

Ball bursting: ASTM D3787 |

||||||

|

|

Download

.pdf file |

||||||

|

|

|

||||||

|

|

|

||||||

|

|

|

||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Random Pilling testing for fabrics. |

||||||

|

|

|

||||||

|

Model options: |

|||||||

|

- |

RPT-2 (2 chamber) |

||||||

|

- |

RPT-4 (4chamber) |

||||||

|

|

|

||||||

|

Features: |

|||||||

|

- |

UPC controller. |

||||||

|

- |

With time and temp. setting

and control. |

||||||

|

- |

Accuration speed & stable

propeller |

||||||

|

|

|||||||

|

Standards ASTM D3512 |

|||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Box type Pilling test for fabrics |

||||||

|

|

|

||||||

|

Model options: |

|||||||

|

- |

ICI-2 (2 chamber) |

||||||

|

- |

ICI-4 (4 chamber) |

||||||

|

|

|||||||

|

Features: |

|||||||

|

- |

UPC controller operation |

||||||

|

- |

Rotation number setting, store and recall. |

||||||

|

- |

Safety device and emergency auto-stop. |

||||||

|

- |

Magnetic

backed cork-liner (simple replacement). |

||||||

|

- |

Easy use sample holder set kit. |

||||||

|

- |

Simple operation with set-up / operation

video. |

||||||

|

- |

Magnetic

backed cork-liner set kit is available for various users(Inquiry

to KMS). |

||||||

|

|

|||||||

|

Standards ISO 12945-1, BS 5811,GB4802-3 |

|||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Matindale abrasion test and pilling test for fabrics |

||||||

|

- |

Lissjous curve |

||||||

|

|

|||||||

|

Features: |

|||||||

|

- |

Userfriendy design |

||||||

|

- |

10 stcored program, can save different abrasion and pilling

count numbers. Recall to test without setting again.

|

||||||

|

- |

Dispaly the

status "abrasion or pilling test" 6 x standalone counting number

setting and actual number display. |

||||||

|

- |

With interrupt

memory record |

||||||

|

- |

Auto up / down platform |

||||||

|

|

|||||||

|

|

|||||||

|

Standards ISO 12495-2, 12947, 5470 /

GB/T4802.02 ASTM D4966, D4970 / IWSTM112,196 JIS1096 |

|||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

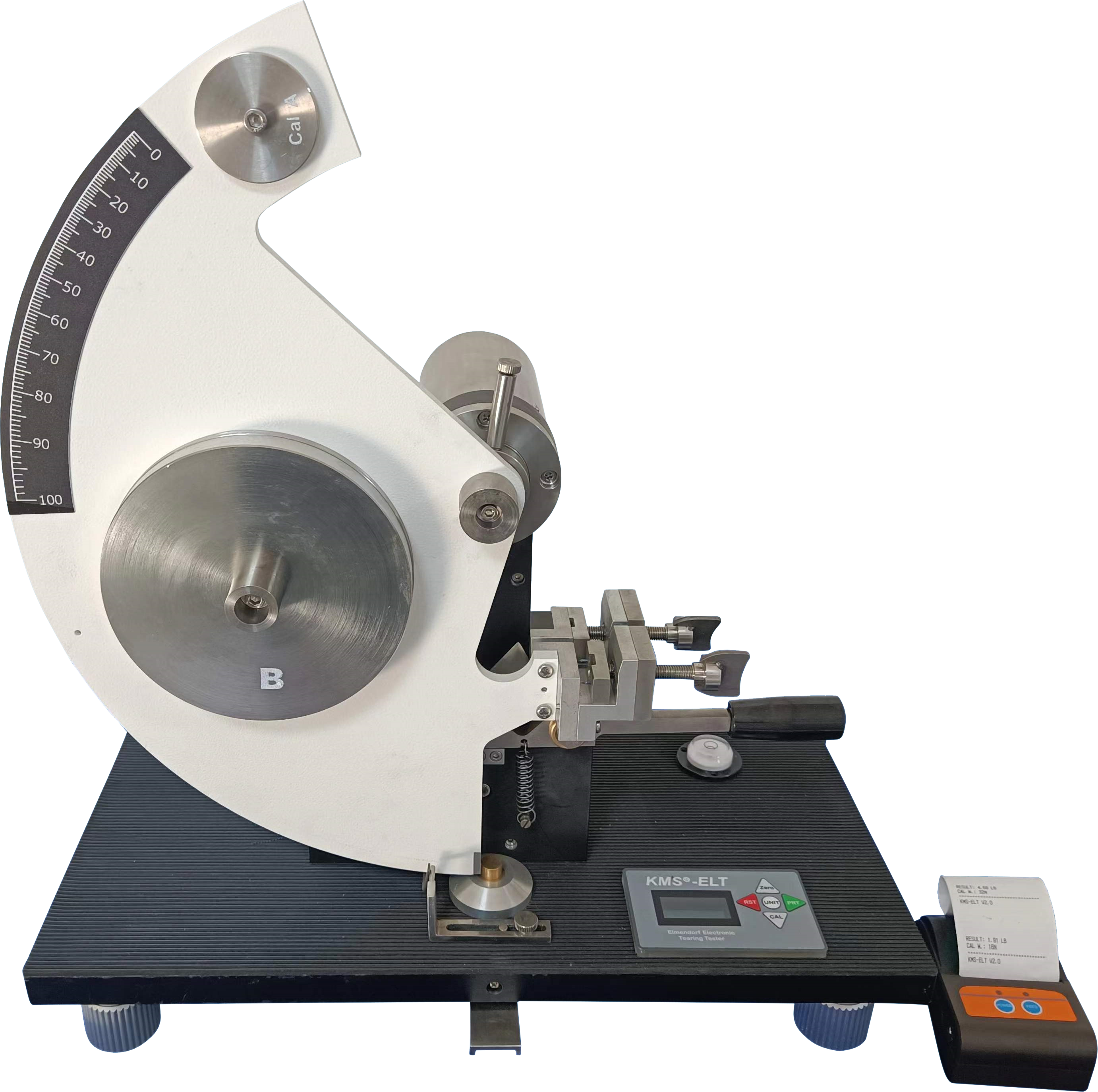

Application: |

|||||||

|

- |

To

determine of woven fabric Elmendorf tear strength. |

||||||

|

Features: |

|||||||

|

- |

With

electronic display of different weight unit, lbs % kg

and N. |

||||||

|

- |

3

x tearing force range 16N, 32N, 64N |

||||||

|

|

|||||||

|

Standards ISO 13937-1 / GB3917.1 / ASTM D1424 |

|||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

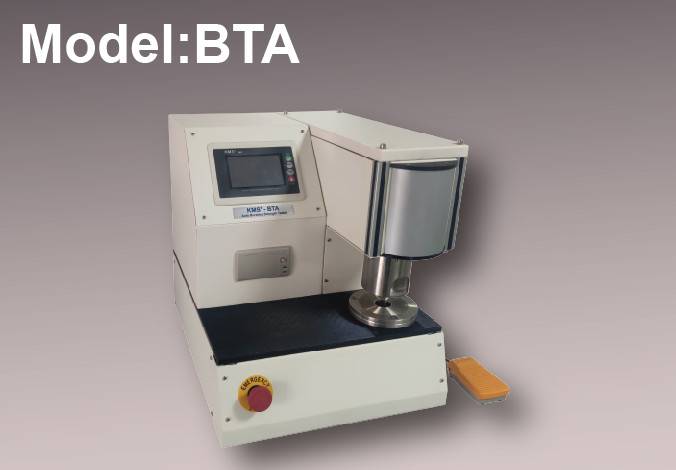

Application: |

|||||||

|

- |

Hydraulic diaphram

bursting strength(Mullen type) |

||||||

|

Features: |

|||||||

|

- |

UPC

graphic type controller. |

||||||

|

- |

software

provided 2 operation method |

||||||

|

- |

Auto

display the bursting strength force in Kpa or Lbs. |

||||||

|

- |

Test

data can be printed by ready build-in narrow printer. |

||||||

|

|

|||||||

|

Standards ASTM 3786, ISO 2758, GB/T454 |

|||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

To determine yarn count. |

||||||

|

Standards ASTM D2260 ASTM D1907 ISO 2060 |

|||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

To determine yarn twisting.in single or

plied yarns |

||||||

|

- |

Test for "S" and "Z"

twist |

||||||

|

|

|||||||

|

Standards ASTM D1422 ASTM D1423 ISO 2061 |

|||||||

|

|

|

||||||

|

|

Download .pdf file |

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Examine the grading of yarn appearance by winding the yarn on the black board. |

||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|

||||||

|

|

|

||||||

|

|

|

||||||

|

|||||||

|

|

|||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|

||||||

|

|

|||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Digital pH/ Thermometer.0-16 pH, 0-90 degree C.complete with probes. |

||||||

|

Features: |

|||||||

|

- |

Digital pH/ Thermometer.0-16 pH, 0-90 degree C.complete with probes. |

||||||

|

|

|

||||||

|

|

Download .pdf

file |

||||||

|

|

|

||||||

|

|

|

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

To simply and economically determine "per unit area" of textile knitting or fabric and calculate the material costs. |

||||||

|

Features: |

|||||||

|

- |

Supply with Germany

Blades. |

||||||

|

- |

Accurately cut out

100 cm2 specimen (diameter 113mm). |

||||||

|

|

|

||||||

|

|

Download .pdf file |

||||||

|

|

|

||||||

|

|

|

||||||

|

|

|||||||

|

|

|||||||

|

Consumables |

|||||||

|

|

|||||||

|

|

On-line water sprayer system |

|

|

||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

- |

AATCC / ISO Grey Scale For Color Change / Color Staining

|

||||||

|

- |

AATCC / ISO Standard Detergent for

Washing colorfastness test |

||||||

|

- |

AATCC / ISO

Multifibre

for colorfastness test |

||||||

|

- |

6mm stainless ball (250pcs/pack) for

Washing colorfastness test |

||||||

|

- |

Test paper, Control fabric, BHT Free film for Yellowing test

|

||||||

|

- |

AATCC / ISO (SDC) Crocking cloths for Rubbing colorfastness test

|

||||||

|

- |

AATCC / ISO SDC Standard Blue Wool for Light Fastness test

|

||||||

|

- |

Pilling grading photo ASTM SM-50

|

||||||

|

- |

Pilling grading photo ISO ISO-12/45-1

|

||||||

|

- |

Pilling grading photo EMPA-9901

|

||||||

|

|

|||||||

|

|

|||||||

|

|||||||

|

|

|||||||

|

Application: |

|||||||

|

- |

Using for Light Cabinet. |

||||||

|

Model: |

|||||||

|

- |

Daylight for SPL-III, CM65 daylight

6500K |

||||||

|

- |

24"/36" CWF(COOL WHITE),

TL84, TL83, U35, UV BLACKLIGHT |

||||||

|

- |

INCA, Horizon |

||||||

|

|

|

||||||

|

|

|

||||||

|

|

|||||||

|

|

/tr>

|||||||

|

|

|||||||

|

KMS Colortech Service Co. Ltd |

|

Tel: (852) 2753 6176(HK) / (86-20) 3473 0153(GZ) E-mail: sales@kmscolor.com |

|

|

Copy right by KMS Colortech Service Co. Ltd |

|